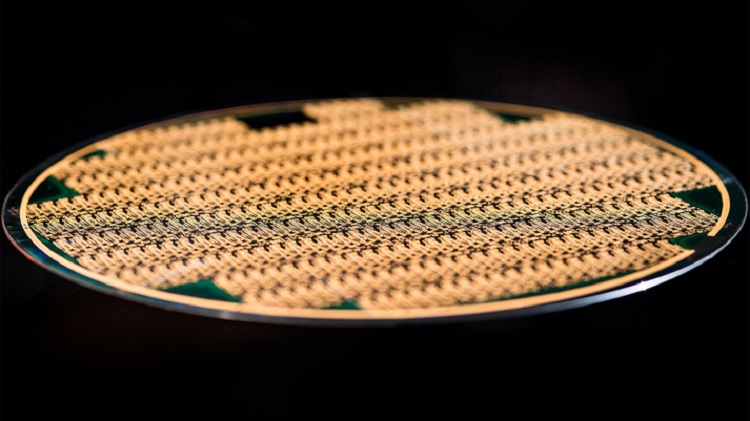

On October 1, McLean, VA-based BAE Systems announced that it has successfully completed a Phase 1 effort to transition short-gate gallium nitride (GaN) semiconductor technology developed by the U.S. Air Force to its Advanced Microwave Products (AMP) Center. The company was also selected by the Air Force Research Laboratory (AFRL) for Phase 2 of the program. The GaN semiconductor technology comes in the form of a wafer that provides high efficiency and broad-frequency bandwidth capabilities in a compact form that can be integrated into a variety of systems to enable next-generation radar, electronic warfare, and communications.

As part of Phase 2, the BAE Systems FAST Labs research and development team and the AMP Center will collaborate to further develop and advance the readiness of the technology. Specifically, the project will scale the 140-nanometer GaN monolithic microwave integrated circuit (MMIC) technology to 6-inch wafers and increase its manufacturing level of maturity as part of the validation process, which will include optimizing performance, ensuring process stability, and maximizing wafer-to-wafer uniformity and wafer yields.

ENGIN-IC, a custom MMIC design company, will support the design activities, including process design kit validation. This technology will transition to a foundry service product, available through BAE’s open foundry service, at the end of Phase 2, where the technology can be leveraged more broadly across different government initiatives.

“Our foundry is a trusted partner to the defense community because it is dedicated to the design, creation, and implementation of vital technologies such as short-gate GaN,” said Chris Rappa, product line director for Radio Frequency, Electronic Warfare, and Advanced Electronics at BAE Systems FAST Labs. “GaN technology fills a unique need for the Department of Defense for low-cost, high-performance amplifier technology, and Phase 2 of this effort brings us one step closer to successfully manufacturing and bringing AFRL’s technology to market.”

Source: BAE Systems